A Machine Learning Tool for Ball-Bearing Fault Detection

Ball bearings are fundamental components in rotating machinery, yet their failure remains one of the leading causes of unplanned downtime and catastrophic machinery failures. Detecting faults at an incipient stage—before they escalate into critical issues—is essential for minimizing disruptions and extending equipment life.

However, early fault detection is challenging because the vibration signatures of a healthy bearing and one with an emerging defect often appear strikingly similar. Common faults, such as cracks or pits on the outer race, inner race, or rolling elements, may initially generate subtle changes that are difficult to distinguish using conventional diagnostic methods.

Enhancing Envelope Detection with PSO

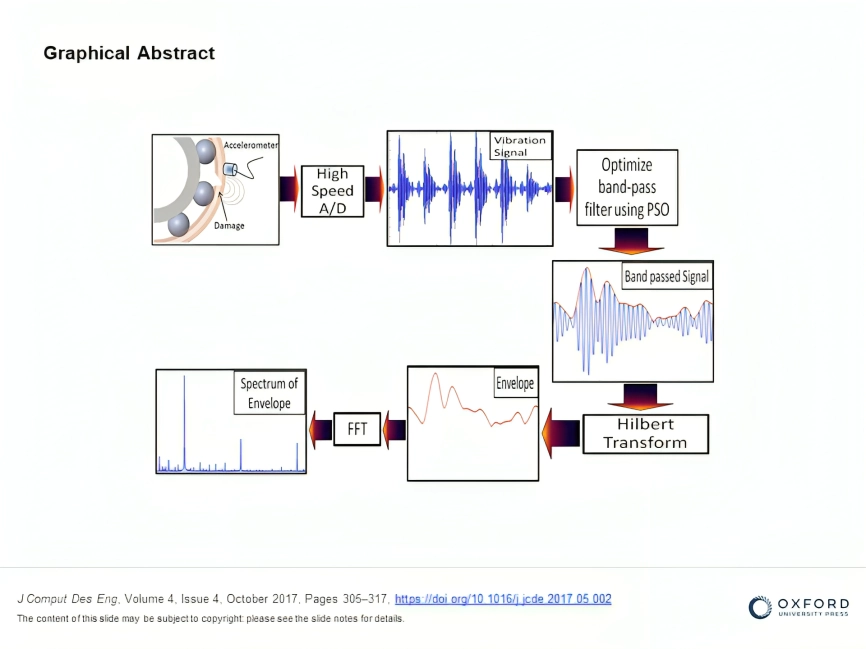

Envelope Detection (ED) is a well-established technique for diagnosing faults in ball bearings by analyzing vibration signals. Traditionally, ED involves band-passing the vibration signal, extracting its envelope, and then applying a Fourier transform to reveal fault-related frequency components.

To overcome this limitation, my research introduced a Particle Swarm Optimization (PSO)-based approach to dynamically optimize the envelope window. By applying PSO, the system intelligently selects the most effective frequency band for processing vibration signals from both healthy and faulty bearings. The Hilbert Transform is then used to extract the envelope, ensuring more precise fault identification.